"The

essential new quality implied by the quantum theory is... that a

system cannot be analyzed into parts. This leads to the radically new

notion of unbroken wholeness of the entire universe. You cannot take

it apart. For if you do, what you end up with is not contained within

the original whole. It is created by the act of analysis." -

David Bohm "The

essential new quality implied by the quantum theory is... that a

system cannot be analyzed into parts. This leads to the radically new

notion of unbroken wholeness of the entire universe. You cannot take

it apart. For if you do, what you end up with is not contained within

the original whole. It is created by the act of analysis." -

David Bohm

Utilizing modern and ancient techniques it is possible to create

buildings that are affordable, non-toxic and interesting

to live and work within. LightEarth Consulting projects

integrate the aspects of economics, human health and environmental

considerations.

Implementing natural materials such as straw bale and

earthen materials with modern high tech (but less toxic) 'green'

products and recycling is at the core of LightEarth's efforts. Many

exciting developments are growing the area of Natural Building. There

is a resurgence in availability and experimentation to synthesize old

and new technologies.

Many areas of the United States (Taos, Austin, Seattle etc.) have

recently embraced this resurgence with thousands of new buildings

created in these more positive modes. We at LightEarth Consulting

are

bringing these same opportunities to the Midwest and Great Lakes

states.

LightEarth will consult and/or build your next project, whether it

is office space, home or barn; working with you to ensure maximum

efficiency of resource usage while minimizing environmental impact.

Frequently Asked Questions

Cob Straw

bale Green Products

Cob (building

with Earth) - Top

What does Cob mean ?

"Cob" is an Old English word referring to building with

earth. Through all the continents and all times people have

housed themselves utilizing natural soils. Variations of Cob are

incorporated in many of the oldest standing buildings today including

pyramids from antiquity and homes that are 500 or more years old in

Europe.

Why hasn't Cob been used recently ?

Only recently in the 20th century has building with earth become

uncommon. In a time of quick and homogenous building materials

Cob fell out of favor with the specialized building trades that create

most modern dwellings. In addition American designers and

builder took quick advantage of new mechanized technologies which

exploited a seeming endless supply of dimensional lumber and other

products. Almost as limitless in America has been the 'slash and

burn' westward type expansion, which finds very little advantage in a

consumption-based economy to creating buildings that will last past a

single lifetime (or less).

What are the ingredients of Cob?

What makes up a Cob building is elegantly simple. Cob is a

ratio mixture of clay, sand and straw typically. Earth

containing some portion of clay and sand is often times available on

or nearby a proposed building site. Straw is in many places a

waste product of cereal grain (wheat, oat, and rice) harvesting and

provides the tensile strength that binds layers of sand and clay with

each other and succeeding layers.

What makes Cob so long lasting ?

A common misconception is that Cob would wash away in rain.

Most Cob buildings are plastered with a lime or otherwise stabilized

(hardened) plaster that runs water off the walls. Cob, once dry,

is very hard and will naturally stay that way if protected from

soaking long term in water. The British Cob builders have passed

on the statement "give Cob a good hat and good goulashes and

she'll last forever....". This simple protection of the

walls is accomplished by creating a foundation to keep the Cob from

soaking up ground water (goulashes) and placing a water-shedding roof

with decent overhangs (hat) on top of the walls. Because the walls are

not susceptible to termites, fire or rot the upkeep of the

remainder of the building determines its longevity.

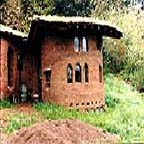

Is there a variety of designs that I can build with Cob?

Now to the really good stuff !!! Being non-linear (not square

or inflexible) Cob can be built in an infinite array of

designs. Because the wall is actually one integral mass it

improves the stability and strength of a Cob wall to build curves into

the design which opens up the possibilities to buildings created from

our finest imaginings. Heart shape, spiral and S curve

walls are some of the many variations that have been tried in modern

Cob buildings. A fantastic array of arches and window

possibilities also add to the aesthetic appeal of a Cob building

without the least bit of additional difficulty.

Built-in elements such as niche's, out flowing benches and arched

earthen fireplaces are just a sample of the creative possibilities.

How do I find out more?

Straw bale - Top

How are straw bales used in buildings ?

The bales can serve as in-filled insulation between post and beam

construction or can be load bearing (sometimes called 'Nebraska

style'), where the roof rests on top of a special collar that

ties the top of the bales together. The bales are alternately

stacked on top of a foundation to keep them dry and basically follow

the shape of this foundation including the ability to bend to some

degree.

What advantage is there to straw bale walls ?

Straw bale wall insulation is its superior quality. The

typically R-40 walls also have a breathing characteristic that

artificial insulators do not in addition to their out gassing of

toxins. Bales represent a quicker regeneration cycle than wood

and can be grown on a site with the grains going for food and the

chaff becoming the wall insulation.

Isn't it a short lived wall ?

Baled straw, as we know it, only goes as far back as the mechanical

baler. Today there are sound examples of early straw bale walled

homes built in the early part of the 20th century. Much like

wood in this way, straw bales must be protected from the elements

(water in particular) or rot will consume its structural

integrity. Given a reasonable amount of protection such as a

roof with overhangs, an impermeable foundation and a maintained

plaster coating, straw bale construction will last for

centuries. Today's baling machines also provide superior

strength bales to many that were built earlier in the 20th century.

Won't it catch fire ?

Tightly baled straw has been proven to burn very poorly. A lack of

air within the bale causes it smolder rather than ignite.

Typically house fires in modern structures gain strength through a

'chimney effect' caused by the air gap between wood studs. This,

in addition to dried woods likeliness to ignite quickly makes non

straw bale wood frame housing more fire susceptible. Wall plasters

(below) further decrease the likelihood of a fire. Using

standard fire testing, plastered straw bale walls have received very

high ratings.

What covers the walls ?

With the recent revival of straw bale construction concrete stucco

has been the major choice for plaster. More recently many

experiments (including GBI's) have been done with earthen-based

plaster. Typically several successive coats an outer coat that

includes lime creates a long lasting, environmentally friendly and

inexpensive plaster.

How do I find out more?

Contact Information - Top

LightEarth Consulting

Email: [email protected]

Web: www.LightEarth.com

Phone Orders: 847-563-3001 x 6189

Fax: 847-563-3001 x 6189

Mobile: 847-331-5237

|